Services:

Community Air Monitoring Plan

Environmental Management

Historical Resources Construction Protection Plan

Construction Air Monitoring Plan

Noise and Air Monitoring

Evaluation of Noise & Air Emissions, and Identification of Controls for Construction Equipment

Classification of Spoils Groundwater and Waste

Evaluation of Hazardous Materials in buildings undergoing demolition

Exposure Monitoring Plan (EMP)

Owner:

MTA Capital Construction

2 Broad Street

New York, NY

Client :

Schiavone Shea and Kiewit (SSK) Constructors JV

150 Meadowlands Parkway, 3rd Floor

Secaucus, NJ 07094

Project Cost: $320,000,000

Project Cost: $1,180,000

Project Overview:

Metropolitan Transportation Authority (MTA) Capital Construction retained Schiavone Shea and Kiewit (SSK) Constructors JV for construction of the 72nd Street Station for a new Second Avenue Subway line in New York City, New York. The project scope includes the extension of shafts to a previously-bored tunnel, the construction of caverns for the station, and relocation and temporary support of utilities. Distinct Engineering Solutions, Inc. (DESI) provides SSK with environmental engineering support, including preparation of the Historical Resources Construction Protection Plan, air & noise monitoring and modeling, and selection of Muck House materials to control air and noise pollution levels of the project.

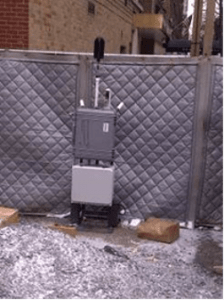

DESI conducted a hazardous material survey for asbestos, lead-based paint, and PCBs, and prepared several plans as part of environmental management, and assisted SSK with implementing them. DESI provided environmental awareness training, characterized subsurface soil & groundwater, and prepared the Community Air Monitoring Plan, the Exposure Monitoring Plan, the Pollution Prevention Plan, and the Soil Erosion Prevention Plan. A Historical Resources Construction Protection Plan was developed for 21 buildings within 200 feet of construction. DESI developed a Noise Control Monitoring and Mitigation Plan, installed the noise monitoring equipment, and evaluated noise levels generated by both on-site and off-site construction equipment. DESI performed baseline air & noise monitoring, and developed site-specific limits. DESI was also involved in groundwater sampling, pretreatment and management, and establishing procedures to meet sustainability requirements. Continuous air and noise monitoring was performed on a real-time basis, with submission of weekly and monthly reports.

DESI performed simulation studies and modeled noise propagation, identified materials to control noise outside of the Muck House, and incorporated dust suppression mechanisms into the Muck House operation to control air pollutants.

This project won an American Council of Engineering Companies (ACEC) of NJ 2013 “Distinguished” Engineering Excellence Award